Well the holidays are behind us, and we’re moving forward on the Bike Cart project.

[slideshow]

It stands to reason that the lighter the trailer is, the more cargo you could carry, if you don’t compromise durability, or weight capacity. That being said, how much difference will a couple of pounds of trailer make? There is no doubt a point of diminishing returns, where you’ve increased the likelihood of a structural failure.

A lot of people are going to fill a trailer to capacity whether it’s feathers or compost, when it starts spilling over the top that’s when it’s full. I think that has to be taken in to account when you build a trailer. Design elements such as the shape and flexibility of the supporting frame members can increase strength, a lot more than adding weight in most cases.

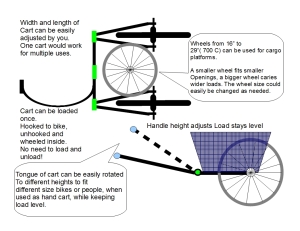

The first thing we are trying is leaving the wheels assembled. A spoked wheel has a lot of strength. When it’s turned horizontal instead of vertical it’s not as strong, but the design shown above was able to support my winter weight of around 180 lbs, or so, with no problem. The tongue of the trailer, the part that connects it to the bike, is made with a 27″ rim split in half and fitted together. Initially this seems to have too much flex, but we think we can eliminate that problem by bolting it together more securely, or maybe stacking the rims vertically instead of fitting them together horizontally. we’ll see how that goes.

There will be a lot more on this subject later. As I said before this process will be reported on as we proceed. Check back often for updates. Input is always welcome.